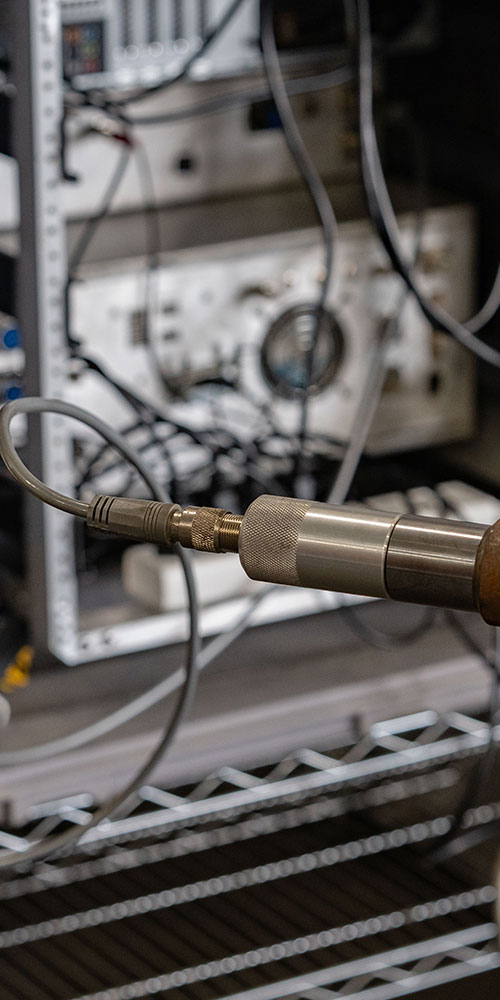

Magnetic Thickness Detector

Features

- Slim tool with 1-11/16” O.D.

- Fast logging of single strings.

- Quantitative three pipe thickness evaluation.

- Qualitative evaluation of fourth pipe.

- A fully configurable tool caters to a wide range of downhole conditions.

- Data can be transmitted in real-time to the surface or stored downhole during memory logging.

Benefits

- Log up to 18-5/8” casing with the same 1-11/16” tool.

- Fully combinable with our full range of logging tools, allowing for one-pass results.

- Cut down on costly runs.

- Capable of evaluating quantitative thickness measurements up to three concentric pipes.

- Slim hole design eliminates the need for pulling production tubing.

- Identify corrosion points of interest in real-time on location.

Magnetic Thickness Detector

About This Product

The WOS Magnetic Thickness Detector (MTD) is a 1-11/16 inch O.D electromagnetic corrosion measuring instrument primarily run through tubing with the unique ability to simultaneously inspect tubing and the casings behind it. The integrity of the casing string can be evaluated with neither the requirement for a costly workover rig nor the time-consuming removal of the tubing completion. WOS’s next-generation MTD tool can evaluate quantitative thickness measurements of up to three concentric pipes. The state-of-the-art instrument combines a high-power transmitter, improved signal-to-noise electronics, and fully configurable acquisition. This flexible approach allows a wide range of evaluations under different conditions and conveyance systems.

Product Details

| Max OD | 1-11/16″ |

| Length | 44.3″ |

| Temperature Rating | 4F – 350F |

| Pressure Rating | 15,000 PSI |

| Logging Speed (single pipe) | 30ft/min |

| Logging Speed (double pipe) | 8ft/min |

| Logging Speed (triple pipe) | 6ft/min |

| Measuring Range | 2.362″ – 18.625″ |

| Temp Resolution | Less than ±1°C |

| Logging Mode | SRO Hybrid, Time, Depth |