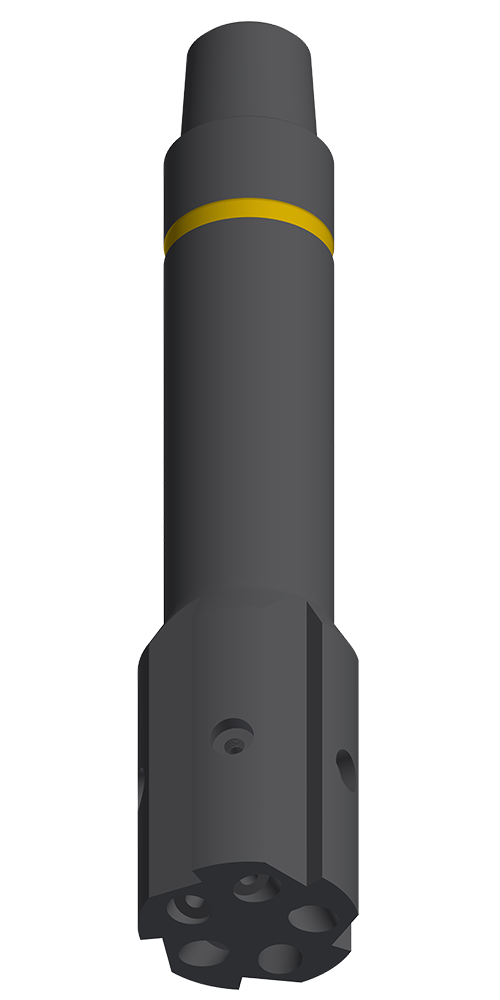

JET Mill™

Features

- In house laid carbide on the face and backside of the mill

- High pressure jet nozzles built into the mill body

- Ability to provide full drift mechanical removal of any hard debris

- All common mill sizes available with custom application options

- Can be ran with standard completion fluids with nitrogen and acid

Benefits

- Reduces fishing jobs with no moving parts

- Reduces trips with re-stimulation and cleanout operation in one run

- Allows for larger hole opening applications blasting away cement and formation

- Better cleaning with high pressure jetting through profiles

JET Mill™

About This Product

The WOS Jet Mill tackles several challenges older producing wells have during restimulation and cleanout operations. Current recompletion work is two-fold, first involves having an operator perform clean out and jetting runs with a motor and junk mill to mill up any debris / scale in the casing or tubing. Secondly, there is a need to provide high pressure jetting to the perforations

or open hole section to cleanup any near wellbore damage.

The WOS Jet Mill provides both in one tool in one single run enhancing production by removing the skin in the well and blockages which are hindering production. The WOS Jet Mill is laid with carbide on the face and backside of the mill and has high pressure jet nozzles built into the mill body. When run with a downhole motor our JET Mill cleans out and mills out any debris in the well with the added benefit of providing high pressure jetting. Operators then can provide full drift mechanical removal of any hard debris / sand and high-pressure jetting to clean perforations / tubing walls all in one run.

Product Details

| Undressed OD (in) | 1.780” – 2.750” | 3.125” – 4.550” | 6.125″ | 8.250″ |

| Fishing Neck OD (in) | 1.700” | 2.875″ | 4.375″ | 5.875″ |

| Fishing Neck Length (in) | 5 – 6″ | 10″ | 8″ | 12” |

| Pin Connection | 1″ MT | 2-3/8” PAC | 3-1/2” REG | 4-1/2” REG |