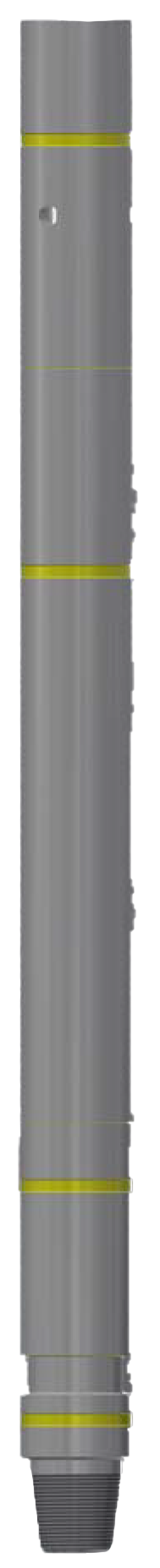

Bit SavR™

Features

- Can be set up to open and close at predetermined weights

- Compatible for use with Extended Reach Tools such as the WOS EaZyDrill or specialty milling tools such as the WOS HammRDrill

- The compact design minimizes additional length and rigidity added to the BHA

Benefits

- Can be run with standard completion fluids and/or nitrogen

- Can be set up to open and close at predetermined weights

- Compatible for use with Extended Reach Tools such as the WOS EaZyDrill or specialty milling tools such as the WOS HammRDrill

- The compact design minimizes additional length and rigidity added to the BHA

Bit SavR™

About This Product

The proprietary WOS BitSavR is a Smart Sub that helps take the guesswork out of controlling bit wear. The smart sub opens and closes based on the transfer of weight at the bit. The BitSavR can be set for varying weight on bit activation as preferred by the operator. This allows for an indication of applied surface WOB to control the amount of weight transferred to the bit. This increased control directly increases the ability of the operator to target weight application and control the amount of wear that is being experienced. The increased ability to control wear will extend the useable life of bits as well as reduce the amount of time necessary to complete a drill-out operation.

Product Details

| Tool Size, in | 3-1/8” |

| Max OD, in | 3.13 |

| Max ID, in | 1.00 |

| Overall Tool Length, in | 46.72″ |

| Shoulder to Shoulder Length, in | 43.85″ |

| Torsional Yield, ft-lbs | 5,500 |

| Top Connection | 2-3/8” REG Box |

| Bottom Connection | 2-3/8” REG Pin |

| Tensile Yield, lbf | 161,200 |